7 Steps to Build a Starling and Sparrow Nest Box Trap

To construct a starling house sparrow nest-box trap, utilize untreated lumber, galvanized screws, and a precision saw for structural durability. Place the nest-box 2.5 to 4 meters above the ground, positioning it away from direct sunlight and strong winds.

Build using natural timber, incorporating corrosion-resistant parts and marine-grade plywood. Add a 1.5-inch entrance hole and a long-lasting trap mechanism.

Ensure proper positioning and utilize mesh hardware cloth for efficiency. Lastly, securely attach the nest-box to a robust tree or pole and conduct routine checks for mechanical and biological effectiveness.

For in-depth construction methods and maintenance approaches, delve further.

Key Takeaways

- Use untreated timber and galvanized screws to construct a durable nest-box.

- Install a 1.5-inch entrance hole to specifically attract starlings and house sparrows.

- Mount the nest-box 2.5 to 4 meters above ground, avoiding direct sunlight and strong winds.

- Incorporate a trap mechanism with high-durability materials and precision-engineered fasteners for secure and efficient trapping.

- Regularly monitor and maintain the trap for mechanical issues and cleanliness to ensure optimal functioning.

Gather Your Materials

To construct an effective starling house sparrow nest-box trap, you will require a specific set of materials. This includes untreated timber, galvanized screws, and a precision saw. Untreated timber is necessary to prevent the leaching of chemicals that could harm birds. Galvanized screws offer superior corrosion resistance, ensuring the longevity of the structure.

Employ a precision saw for accurate cuts, maintaining tight tolerances essential for the trap's integrity. Additional materials include a 1.5-inch entrance hole saw bit to match the ideal entry diameter for starlings, ensuring selective entry. Use waterproof wood glue to strengthen joints and weatherproof the box.

Choose a Suitable Location

Selecting an ideal location for the starling house sparrow nest-box trap is important for maximizing its effectiveness and ensuring the safety of non-target bird species. The chosen site should be strategically selected based on the behavioral patterns and habitat preferences of the target species.

Best placement considerations include:

- Elevation: Position the trap approximately 10-15 feet above ground to mimic the preferred nesting height of starlings and house sparrows.

- Proximity: Locate the trap near frequent feeding or perching sites to increase the likelihood of attracting the target species.

- Orientation: Face the entrance hole towards an open area, avoiding direct sunlight and prevailing winds to maintain a hospitable internal environment.

- Vegetation: Guarantee minimal dense foliage around the trap to prevent easy access for predators and non-target species.

These criteria will enhance the trap's functionality and minimize ecological disruptions.

Construct the Nest-Box

Initiating the construction of the nest-box requires the acquisition of specific materials, including untreated wood, screws, and predator guards.

Precise measurements and accurate cuts are critical to guarantee all components fit seamlessly, maintaining structural integrity.

Following the cut, the assembly process involves methodical alignment and securing of panels to create a robust and functional nest-box.

Gather Necessary Materials

Assembling an effective Starling House Sparrow nest-box trap requires a precise selection of materials. This includes natural wood, corrosion-resistant screws, and suitable mesh sizes to guarantee both durability and functionality.

Utilizing natural wood ensures the absence of harmful chemicals that could deter birds. Corrosion-resistant screws resist rust, maintaining structural integrity over time. Selecting the correct mesh size is crucial in preventing escape while allowing adequate ventilation.

For best results, the following materials are recommended:

- Natural wood: Preferably cedar or pine, known for their innate resistance to decay.

- Corrosion-resistant screws: To provide strength and resilience to environmental degradation.

- Mesh hardware cloth: With a quarter-inch grid for effective containment and ventilation.

- Water-resistant wood glue: To secure a lasting and enduring assembly.

These components form the foundational elements for a sturdy and functional nest-box trap.

Measure and Cut Wood

To guarantee accurate assembly of the nest-box, begin by carefully measuring and cutting the natural wood to the specified dimensions using a high-quality saw. Start by marking the wood with a carpenter's pencil and a steel ruler or tape measure, ensuring all lines are precise.

The primary dimensions include the front panel, back panel, side panels, base, and roof. Use a miter saw or circular saw for clean, straight cuts, maintaining a consistent hand to prevent jagged edges. For best results, select weather-resistant wood, such as cedar or pine, to enhance durability.

Assemble Nest-Box Components

Once the wood components are accurately cut, the assembly process begins by aligning the front and back panels with the side panels, maintaining precise joint alignment for optimal structural integrity. Pre-drill pilot holes to prevent wood splitting, then secure panels using screws that can withstand different weather conditions.

Attach the base by aligning it flush with the bottom edges of the side panels, maintaining a square assembly. Use exterior-grade wood adhesive for additional strength at all joints.

- Pre-drill all screw holes: This reduces the chance of wood splitting and ensures smooth screw insertion.

- Weather-resistant screws: These uphold structural integrity in varying environmental conditions.

- Exterior-grade wood adhesive: Enhances joint strength and durability.

- Square assembly check: Confirms the nest-box remains aligned and properly constructed.

Precise assembly guarantees a sturdy and functional nest-box trap.

Install the Trap Mechanism

To guarantee the trap mechanism functions at its best, it is imperative to select materials with high durability and resistance to environmental stressors.

The mechanism must be securely affixed to the nest-box structure, utilizing precision-engineered fasteners to prevent any dislodgement.

Rigorous testing of the trap functionality should be conducted to validate its efficacy in humanely capturing target species without causing harm.

Choose Appropriate Materials

Selecting the appropriate materials for installing the trap mechanism involves understanding the specific properties of each component to guarantee functionality and durability in varying environmental conditions. Each material must be chosen for its resilience, compatibility, and performance under different weather patterns and pressures.

Key materials to ponder include:

- Galvanized Steel: Provides superior rust resistance and structural integrity, essential for outdoor exposure.

- Marine-Grade Plywood: Offers high durability and moisture resistance, ensuring longevity of the trap housing.

- High-Tensile Springs: Ensures reliable and consistent actuation of the trap mechanism, crucial for effective operation.

- Weatherproof Fasteners: Stainless steel screws or bolts to prevent corrosion and maintain secure assembly over time.

Selecting these materials will optimize the trap's performance and extend its operational lifespan.

Securely Attach Mechanism

Precisely aligning and fastening the trap mechanism within the nest-box is essential to guarantee peak functionality and dependable performance under varying environmental conditions. Begin by positioning the trap mechanism at the best location inside the nest-box, ensuring uniform spacing to avoid any operational hindrance. Use corrosion-resistant screws and washers to secure the unit firmly. Employ a torque wrench to achieve the recommended torque value, avoiding overtightening that might damage the housing.

| Component | Action Required |

|---|---|

| Trap Mechanism | Align with nest-box interior |

| Fasteners (screws) | Use corrosion-resistant screws |

| Torque Wrench | Apply recommended torque values |

Meticulous installation facilitates smooth trap activation and deactivation cycles, ensuring both efficacy and longevity of the system.

Test Trap Functionality

Verifying the trap mechanism operates correctly involves a series of systematic tests to confirm its functionality and reliability under simulated conditions.

Begin by closely observing the sensitivity of the trigger mechanism to confirm it activates with minimal force, replicating the weight of a bird.

Conduct multiple trials to validate the trap door closes completely and securely each time the trigger is engaged.

Validate the structural integrity of the materials and connections under stress to prevent any potential failure during actual use.

Evaluate the ease of resetting the trap to validate it can be efficiently reused.

- Trigger Sensitivity: Test with varying weights to simulate bird interaction.

- Door Closure: Confirm it locks securely upon activation.

- Material Integrity: Assess for durability under stress.

- Reset Mechanism: Verify quick and reliable reactivation.

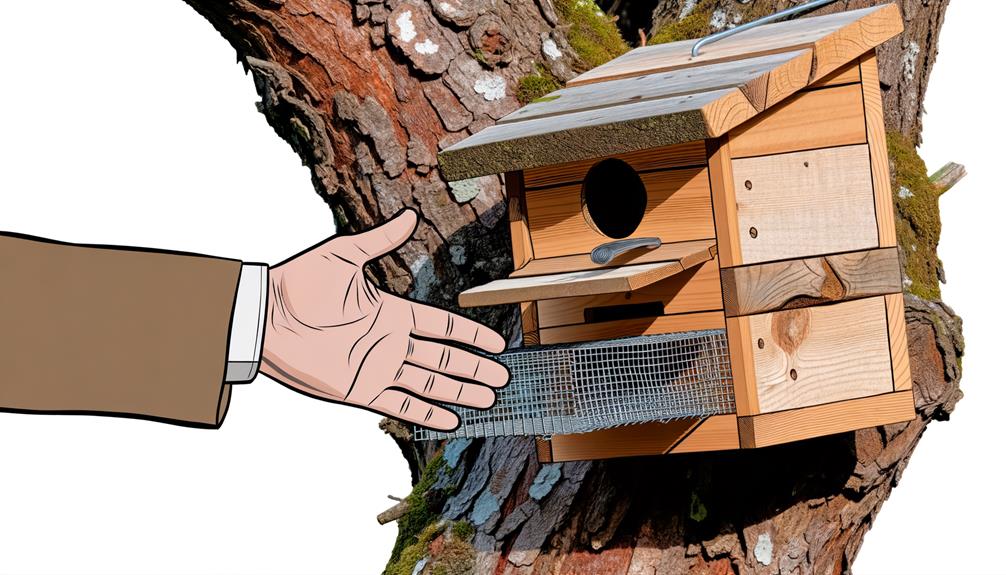

Secure and Mount the Nest-Box

Mounting the nest-box requires selecting a location that offers ideal height, stability, and protection from environmental elements and predators. Best height for starling and house sparrow traps is typically between 2.5 to 4 meters above ground.

Affix the box to a sturdy tree or pole using galvanized screws or robust brackets to maintain structural integrity. Position the entrance hole facing away from prevailing winds to minimize exposure to rain and maintain internal microclimate stability.

To deter predators, consider installing baffles or predator guards on the mounting pole. Additionally, secure the nest-box in an area with minimal human disturbance to encourage avian occupancy. This strategic placement will enhance the effectiveness and longevity of the nest-box trap.

Monitor and Maintain the Trap

Regularly monitoring and maintaining the trap is necessary for ensuring its best functionality and effectiveness in capturing target bird species. Regular inspections facilitate early detection of any mechanical issues, while prompt cleaning prevents contamination and disease spread. Observing the trap's surroundings and the behavior of captured birds can provide valuable insights into trap placement and efficacy.

Inspect Mechanisms: Routinely check the trap's moving parts for wear and tear, ensuring the door and trigger mechanisms function smoothly.

Clean Regularly: Remove debris and sanitize the trap to prevent pathogen accumulation.

Record Data: Document capture rates and species to refine trapping strategies.

Evaluate Placement: Periodically assess trap location for optimal positioning relative to bird activity patterns.

These practices are essential for maintaining a reliable and humane trapping system.

Conclusion

The construction of a starling house sparrow nest-box trap juxtaposes the simplicity of common materials with the complexity of avian behavioral control. Through precise architectural design, strategic placement, and meticulous maintenance, the nest-box trap effectively mitigates invasive species while fostering indigenous bird populations.

This synthesis of practical craftsmanship and ecological science underscores the imperative for methodical intervention in avian population management, highlighting the delicate balance between human ingenuity and natural ecosystems.